标准样品

HS-20MG

HS-20MG is one of the height standards introduced by BudgetSensors as a response to the increased demand for affordable high-quality AFM calibration standards. The HS-20MG features Silicon Dioxide structure arrays on a 5x5mm Silicon chip. The fabrication process guarantees excellent uniformity of the structures across the chip. This in turn ensures easy and reliable Z-axis calibration of your AFM system.The calibration area is situated in the center of the chip. It is easy to find with the AFM optical system. The structure step height is in the range of 20nm. The exact value for each chip is indicated on the box label. Arrays of structures with different shape and pitch are integrated on the chip. The larger square (1x1mm) contains square pillars and holes with a 10µm pitch. The smaller square (500x500µm) contains circular pillars and holes as well as lines in the X- and Y-direction with a 5µm pitch. Aside from Z-axis calibration, this design also allows X- and Y-axis calibration for bigger scanners (40-100µm range). What is more, the structure symmetry makes it possible to calibrate your AFM system without the need to rotate and realign the sample in-between X- and Y-axis calibration. The HS-20MG chip is glued onto a 12mm metal disc using a high-quality electrically-conductive epoxy resin and it is ready for use as shipped.

Technical data at a glance:

Die size:

5x5mm

Step height:

~20nm, the precise value is stated on the label of each box

Structure geometry:

- square holes and pillars with a 10µm pitch arranged in a 1x1mm square

- circular pillars and holes, and lines in the x- and y-direction with a 5µm pitch arranged in a 500x500µm square

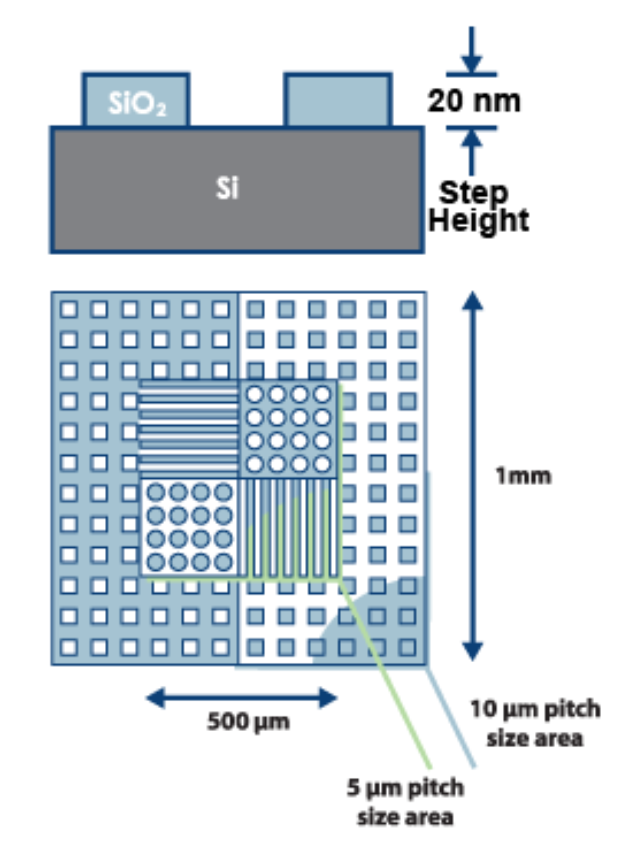

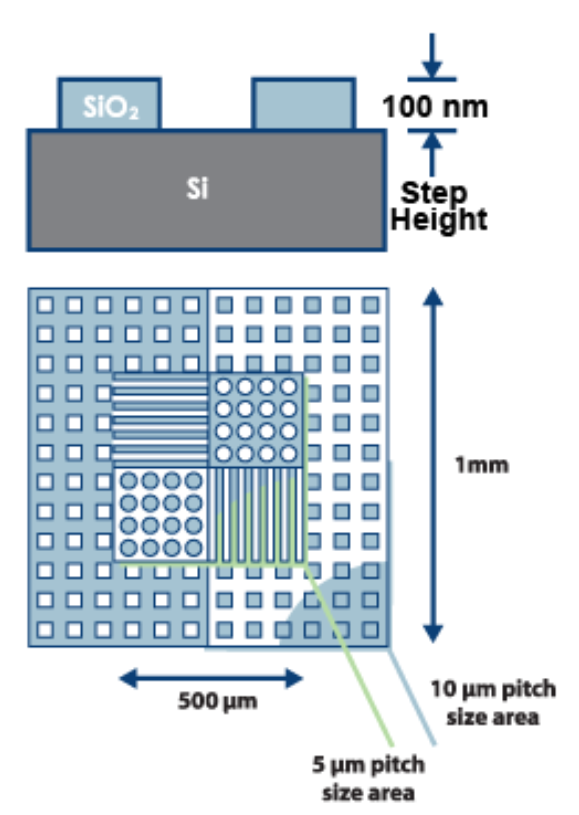

HS-100MG

HS-100MG is one of the height standards introduced by BudgetSensors as a response to the increased demand for affordable high-quality AFM calibration standards. The HS-100MG features Silicon Dioxide structure arrays on a 5x5mm Silicon chip. The fabrication process guarantees excellent uniformity of the structures across the chip. This in turn ensures easy and reliable Z-axis calibration of your AFM system. The calibration area is situated in the center of the chip. It is easy to find with the AFM optical system. The structure step height is in the range of 100nm. The exact value for each chip is indicated on the box label. Arrays of structures with different shape and pitch are integrated on the chip. The larger square (1x1mm) contains square pillars and holes with a 10µm pitch. The smaller square (500x500µm) contains circular pillars and holes as well as lines in the X- and Y-direction with a 5µm pitch. Aside from Z-axis calibration, this design also allows X- and Y-axis calibration for bigger scanners (40-100µm range). What is more, the structure symmetry makes it possible to calibrate your AFM system without the need to rotate and realign the sample in-between X- and Y-axis calibration. The HS-100MG chip is glued onto a 12mm metal disc using a high-quality electrically-conductive epoxy resin and it is ready for use as shipped.

Technical data at a glance:

Die size:

5x5mm

Step height:

~100nm, the precise value is stated on the label of each box

Structure geometry:

- square holes and pillars with a 10µm pitch arranged in a 1x1mm square

- circular pillars and holes, and lines in the x- and y-direction with a 5µm pitch arranged in a 500x500µm square

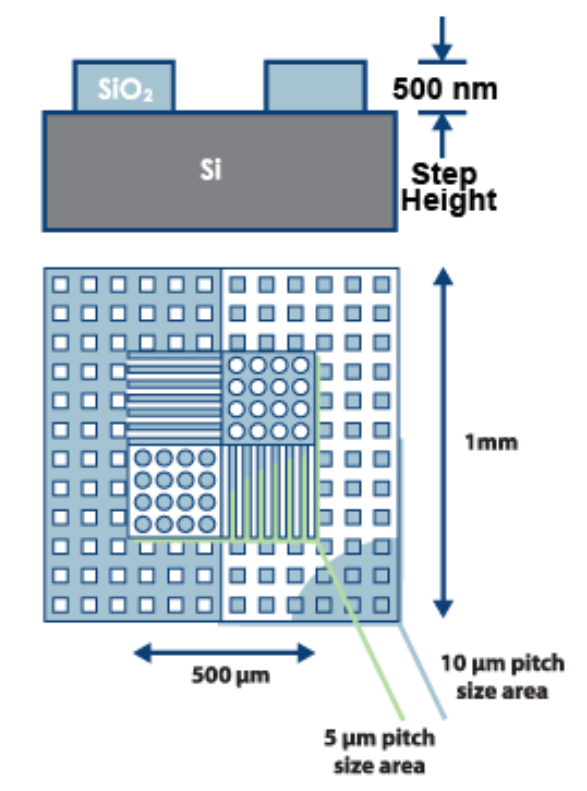

HS-500MG

HS-500MG is one of the height standards introduced by BudgetSensors as a response to the increased demand for affordable high-quality AFM calibration standards. The HS-500MG features Silicon Dioxide structure arrays on a 5x5mm Silicon chip. The fabrication process guarantees excellent uniformity of the structures across the chip. This in turn ensures easy and reliable Z-axis calibration of your AFM system. The calibration area is situated in the center of the chip. It is easy to find with the AFM optical system. The structure step height is in the range of 500nm. The exact value for each chip is indicated on the box label. Arrays of structures with different shape and pitch are integrated on the chip. The larger square (1x1mm) contains square pillars and holes with a 10µm pitch. The smaller square (500x500µm) contains circular pillars and holes as well as lines in the X- and Y-direction with a 5µm pitch. Aside from Z-axis calibration, this design also allows X- and Y-axis calibration for bigger scanners (40-100µm range). What is more, the structure symmetry makes it possible to calibrate your AFM system without the need to rotate and realign the sample in-between X- and Y-axis calibration. The HS-500MG chip is glued onto a 12mm metal disc using a high-quality electrically-conductive epoxy resin and it is ready for use as shipped.

Technical data at a glance:

Die size:

5x5mm

Step height:

~500nm, the precise value is stated on the label of each box

Structure geometry:

- square holes and pillars with a 10µm pitch arranged in a 1x1mm square

- circular pillars and holes, and lines in the x- and y-direction with a 5µm pitch arranged in a 500x500µm square

CS-20NG

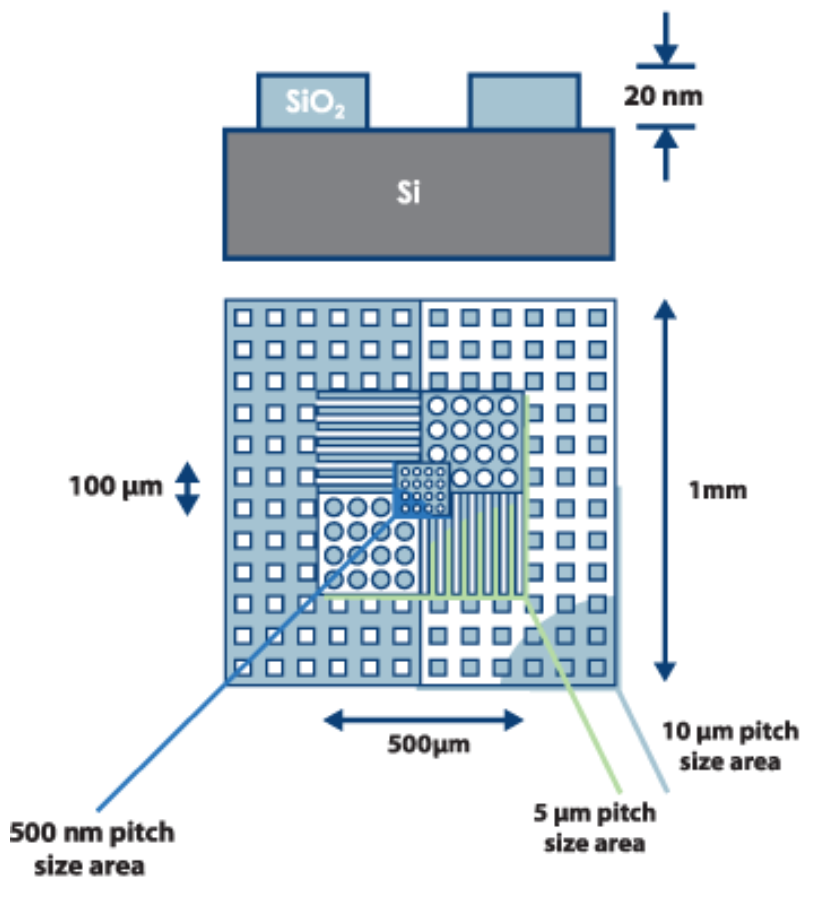

CS-20NG is an advanced XYZ calibration nanogrid that enables calibration up to the nanometer level. It features silicon dioxide structure arrays on a 5x5 mm silicon chip. The fabrication process guarantees excellent uniformity of the structures across the chip. This in turn ensures easy and reliable X, Y and Z axis calibration of your AFM system. The calibration area is situated in the center of the chip. It is easy to find with the AFM optical system. The structure step height is in the range of 20 nm. The exact value for each chip is indicated on the box label. Arrays of structures with different shape and pitch are integrated on the chip. The large square (1x1 mm) contains square pillars and holes with a 10 um pitch. The middle square contains circular pillars and holes as well as lines in the X- and Y-direction with a 5 um pitch. The small square contains circular holes with a 500 nm pitch. The CS-20NG is suitable for both lateral and vertical AFM scanner calibration. The structure symmetry makes it possible to calibrate your AFM system in one step without rotating the sample in-between X- and Y-axis calibration. The CS-20NG chip is glued onto a 12 mm metal disc using a high-quality electrically conductive epoxy resin and it is ready for use as shipped.

Technical data at a glance:

Die size:

5x5mm

Step height:

~20nm, the precise value is stated on the label of each box

Structure geometry:

- Square holes and pillars with 10um pitch arranged in a 1x1mm square

- Circular pillars and holes, and lines in the x- and y- direction with a 5um pitch

arranged in a 500x500um square

- Circular holes with a 500nm pitch arranged in a 100x100um square